The Department of Mechanical Engineering has implemented a thorough practical education system. To nurture students’ abilities for research, development, and the practical application of science and technology, the department places a strong emphasis on experiential learning. Throughout their studies, students have numerous opportunities to engage in comprehensive practical experience. In addition to on-campus practical teaching, the department provides students with internships and training in engineering practices through collaborations with enterprises. This approach enables them to be more independent, innovative, and well-rounded, with hands-on and experimental experiences.

The department recognizes the paramount importance of reforming practical education. In recent years, in an effort to enhance practical education for undergraduates, the department has organized numerous symposiums. These events involve in-depth research on esteemed foreign institutions such as Pennsylvania State University and Worcester Polytechnic Institute (WPI) in the United States, as well as the Department of Mechanical Engineering at RWTH Aachen University in Germany. Additionally, the department has invited educators from these foreign universities to attend the symposiums to have face-to-face exchanges with its faculty members. The two parties have exchanged insights on practical education and shared their practical teaching experiences. Drawing upon advanced educational practices from abroad and considering the actual conditions in China, as well as those specific to the university and department, the department has developed the content and structure for its practical education. Over recent years, adjustments and enhancements to the content and structure have been consistently made based on teaching practices. For instance, since 2005, there has been more emphasis on the role of supervisors during undergraduates’ production internships. In these internships, supervisors not only deliver relevant lectures but also provide specific guidance on the actual products and their process engineering. Additionally, teaching laboratories have been established for disciplines such as electromechanical control, testing technology, engineering materials, and manufacturing systems. In recent years, the department has improved the experimental content within core courses and strengthened existing practical sessions. It has also introduced specialized, comprehensive, and research-oriented practical courses in fields such as modern manufacturing, electromechanical control, material processing, and mechanical design. Take the course series Fundamentals of Mechanical Design and Manufacturing for example. In addition to theoretical teaching, this series, supported by Tsinghua University’s National Education Base for Foundation Courses in Engineering (Mechanical Engineering), annually conducts about 10,000 student hours of general experiments and 8,000 student hours of design and research-oriented experiments. Moreover, to develop undergraduate students’ essential research skills, the department offers specialized training sessions and enhanced guidance on extracurricular Student Research Training (SRT), thus forming an integrated and continuous practical education system throughout the undergraduate program.

In general, the practical education system of the department comprises four main levels:

(1) Experiments in Course Teaching:

Practical courses such as Course Design for Mechanical Design, Introduction to Modern Manufacturing Systems and Experiments, Practical Applications of Electromechanical Control Systems, Basic Control Engineering Experiments, and Material Processing Experiment Series are included in the education plan for the Mechanical Engineering and Automation major. Moreover, in courses like Fundamentals of Engineering Materials, Engineering Materials, Microcomputer Control of Mechanical Systems, Fundamentals of Testing and Inspection Technology, and Fundamentals and Applications of Robotics Engineering, students can engage in relevant experiments with comprehensive or design-oriented practical content.

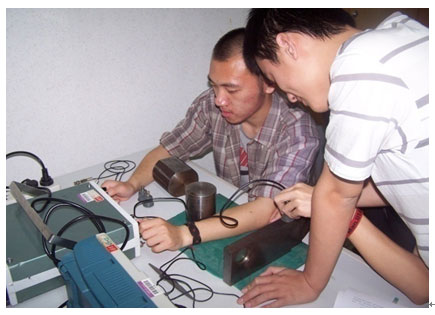

The following pictures depict student involvement in experimental education.

Undergraduate students conducting an ultrasonic inspection experiment

Discussion on the failure analysis of mechanical components

(2) Comprehensive or Research-oriented Specialized Practical Courses: Thematic Training and SRT

The “thematic training” course is designed to allow for early engagement of students in laboratory and research activities under the guidance of teachers. The objective is to enhance students’ skills in knowledge acquisition, independent thinking, self-directed research, and innovation. Additionally, it gives students a clear picture of the nature of research activities in the fields of mechanical engineering and material engineering. Through thematic training, a long-term and direct interaction is established for the first time between students and teachers. This offers students firsthand knowledge of the teachers’ scientific research and a clearer understanding of the research activities within the laboratory.

The Student Research Training (SRT) program is designed to improve students’ scientific research capabilities. It is a measure of teaching reform with the goal to cultivate innovation consciousness and skills among students. By providing undergraduates with early-stage scientific research training, the program allows for their understanding of the university’s and the department’s research landscape. Additionally, it serves as a platform for students to refine their skills in scientific research and enhance organizational and communication abilities. Since the latter half of 2002, a total of 368 projects have been initiated, attracting 654 applicants with a participation rate exceeding 60%. The SRT programs boast a diverse array, covering literature research, novelty retrieval, material property testing, mechanical design, circuit debugging, software programming, and research in material processing technology, among others. Recognizing the vital role of SRT, the department has consistently received the Tsinghua University SRT Excellent Organization Award for 7 years in a row, and 20 projects have been honored with the university’s SRT Excellence Award.

(3) Product-based Production Internships

Throughout product-based production internships, students get to know both the production processes and processing technologies of the essential components of typical products. They also have some knowledge of the organizational structures and quality assurance systems within enterprises. This hands-on experience fosters a deeper understanding of the significance and the role of material processing in the machinery manufacturing industry.

Since 2005, the department has been actively exploring innovative approaches to production internships. This effort involves not only deepening collaboration with enterprises through the establishment of practice bases but also forging partnerships with renowned foreign universities to create a sustainable mechanism for talent cultivation through practical training. The First Inner Mongolia Machinery Group is a pivotal enterprise within the science, technology, and industry sector dedicated to national defense. It stands as an ideal location for the production internship of undergraduates majoring in Mechanical Engineering and Automation. The department has thus forged a robust, long-term partnership with the group and designated it as a production internship site for undergraduates. Efforts have been made to enhance the educational sessions within this internship program. These measures include the appointment of experienced industry technicians as instructors and the issuance of appointment certificates, all aimed at elevating the overall quality of the production internship base. Internship sites have also been established at Changchun FAW Automobile and Angang Steel. Additionally, students of this major have participated in internships at various locations, including the 014 Base in Luoyang, the Shanghai-based DMG Processing Center and Seco Tools, the 13th Research Institute of the China Electronics Technology Group Corporation in Shijiazhuang, the Jiangsu-based Foxconn, and Technische Universität Berlin in Germany.

In 2005, the department was honored with Tsinghua University’s Gold Medal of Production Internship, with the promotion of its production internship experiences within the university.

(4) Comprehensive Thesis Training

Comprehensive thesis training (graduation project/thesis) is an essential element for every undergraduate student in order to achieve the objectives outlined in the university’s education plan. It is a holistic approach to enhance students’ fundamental problem-solving skills and nurture their innovation consciousness and abilities. In this training session, students are expected to apply the knowledge they have acquired by conducting a research project or a relevant comprehensive training task under the guidance of their supervisors. Additionally, they are required to independently produce a thesis as their bachelor’s degree thesis.