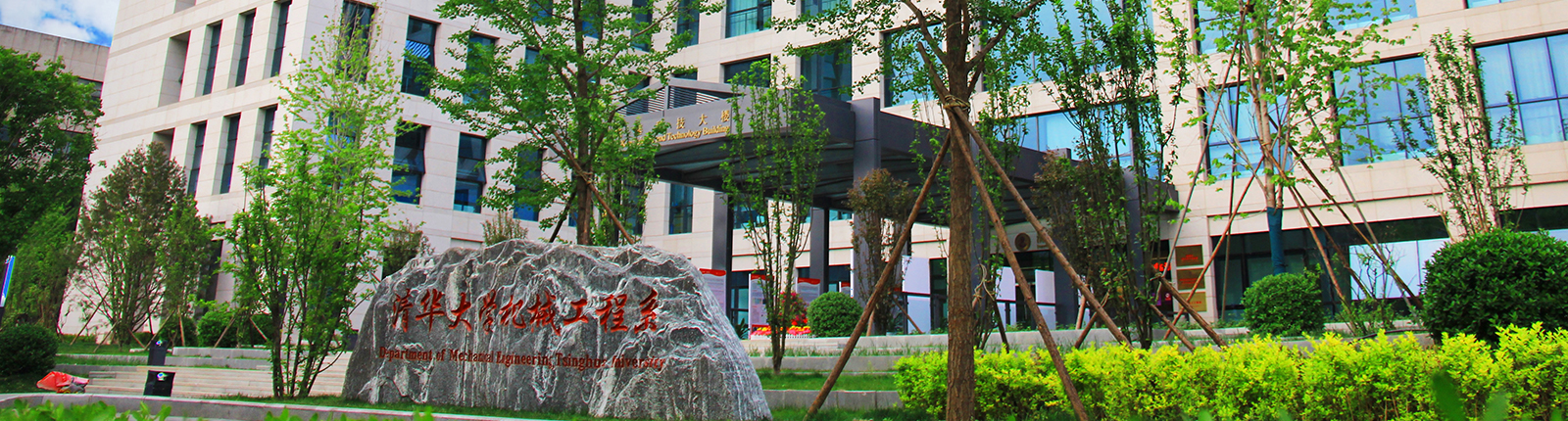

Overview

The DME currently offers programs in three disciplines: Mechanical Design, Manufacturing Engineering and Forming & Manufacturing, under which six research institutes have been established, respectively for Design Engineering, Tribology, Manufacturing Engineering, Mechatronic Engineering, Materials Forming, and Forming Equipment and Automation, as well as the State Key Laboratory of Tribology, the National CIMS Engineering Research Center, the MoE Key Laboratory of Advanced Forming, Beijing Key Laboratory of Precision and Ultra-Precision Machining Equipment and Control, and Beijing Key Laboratory of Biofabrication and Rapid Prototyping Technology. Tianjin Research Institute for Advanced Equipment, Tsinghua University was established in Dongli District, Tianjin in 2014. It worked with RWTH Aachen University in Germany to establish the International Joint Research Laboratory for Innovative Design and Manufacturing of Advanced Equipment in 2015. Then in 2016, it was approved to establish Beijing Municipal Sci-Tech Cooperation Base for Innovative Design and Manufacturing of Advanced Equipment, which becomes another platform for the DME in technology transfer and international cooperation.

The DME orients its scientific research to international discipline frontiers and major national demands, and carries out basic research and advanced technology development in the fields of aviation and aerospace, energy equipment, transportation, IC equipment, biomedical engineering, etc. The main research directions include: digital design and analysis, basic tribology theory and technology, micro/nano mechanics and tribology, surface interface theory and technology, mechanical parts and sealing technology, mechanical system dynamics and fault diagnosis technology, biomechanical systems and rehabilitation engineering, advanced manufacturing equipment and control, precision and special processing technology, robotics, IC manufacturing equipment, manufacturing system automation and digitization, forming theory and computer simulation, heavy equipment design and manufacturing, forming process monitoring control and automation, Laser processing, additive manufacturing and bio-3D printing, aerospace manufacturing engineering, etc.

The DME has made many "pioneering" contributions to China's scientific and technological development over the past periods. In 1958, the DME developed the first CNC machine tool in China, almost simultaneously with the United States, the Soviet Union, and Japan, which won the New Technology Award from the State Scientific and Technological Commission. In the 1960s, it was engaged in the welding and manufacturing of China's first nuclear reactor shell, and worked with companies in developing China's first vacuum electron beam welder, the first 60MN free forging hydraulic press, the first split cone milling machine, etc. In the 1970s, it developed several semiconductor processing machines, such as step and repeat automatic cameras, pattern generators, photolithography machines, electron beam exposure machine wafer stages, etc., and participated in the development of China's first prestressed steel wire-winding 15MN hot isostatic press, and introduced the "Equal Shear Stress Winding Theory" to the world for the first time.

Tel:010-62772677

E-MAIL:mayue@tsinghua.edu.cn

Address:A401, Department of Mechanical Engineering, Tsinghua University, Wudaokou, Haidian District, Beijing(School Map)

Department Official Micro

Mechanical Orthophonia

Sound Of Machinery

Alumni Chapters

Copyright © 2024 Dept. of Mechanical Engineering Tsinghua University. All rights reserved.